Foreword

For nearly ten years in the global business of tool bags, we have dealt with a wide variety of clients. Since the order quantity planned by some clients can not reach the MOQ, we have lost many opportunities to cooperate with new clients. Therefore, I hope to share the knowledge of the MOQ of tool bag bulk sourcing through this article, so as to help the global tool bag buyers to make better purchasing plan.

The MOQ of Tool Bag Bulk Sourcing described in this article applies to tool bag global B2B sourcing, international bulk trade orders and wholesale orders, not retail. This article will let you know why there is MOQ in tool bag bulk sourcing and teach you what to do when the purchase quantity is lower than the MOQ and how to make the MOQ lower.

What Is MOQ Of Tool Bag Bulk Sourcing?

A term used in trade to determine a product’s minimum number of pieces to place an order.–Wikipedia

In the tool bag B2B bulk sourcing, MOQ is the minimum order quantity calculated by the tool bag factory according to the customer’s order requirements. If the order quantity is lower than the MOQ, Tool bag factories are unable to accept orders because they cannot schedule production or get profit. Simply put, MOQ is the lowest quantity of goods ordered by clients that factory can accept. For more knowledge about generalized MOQ, please check this article–Minimum Order Quantity (MOQ): Formula, Tips, & Benefits.

Why There Is MOQ In Tool Bag Bulk Sourcing?

In the field of tool bags, tool bag manufacturing consists of many processes, each process is operated by the corresponding department, and the various departments of the tool bag factory have to cooperate with each other to produce.

The following are several main factors that generate MOQ of tool bag bulk sourcing, I will help you understand by giving some examples.

Quality Guarantee

“Quality First” is the principle of our factory. In tool bags manufacturing, each order requires each process to run in with each other, and each process has separate production adaptation period, In short, in the early stage of every production process, the production speed is from slow to fast, and the damaged product rate is from high to low. Therefore, in order to guarantee the quality, the factory have to set the MOQ.

Cost Control

Work Efficiency

We know that factories have to pay wages to workers. In manufacturing tool bags, The time cost per order for some processes is almost the same, such as material preparation, this process is usually operated by the staff of the material warehouse. Before an order starts to be produced, the warehouse staff needs to count and prepare all the materials required for the order.

Assume the usage of rubber logo for 1000pcs tool bags is 1000 pcs and the usage of rubber logo for 100pcs tool bags is 100 pcs,there is practically no difference in the time it takes for staff to count and prepare 100 pcs and 1000 pcs rubber logos,if the order quantity is 1000 pcs, the staff counts 1000 rubber logos and hand them over to the workshop department, if the order quantity is 100 pcs, the staff counts 100 pcs rubber logos and hand them over to the workshop department, the time it takes is same! Then we can think about it, assuming that the monthly salary of that staff is X RMB and he can process 100 orders per month. If the factory gets 100 orders of 1000pcs the Z model per month, one staff can process all the orders,but if the factory gets 1000 orders of 100 pcs Z model per month, 10 staffs are needed to process these orders, which means that the factory needs to pay 10X RMB per month to these staffs,It is worth noting that 100*1000=1000*100—that is to say the profit of order is the same yet the staff wages much higher.

On the other hand, we take the sewing speed of sewing workers as an example,sewing workers get almost same time adaptation period when they sews every batch of the tool bags,during the adaptation period, the sewing speed is from slow to fast, after the adaptation period, the sewing speed is basically stable, although the adaptation period will be shorter for experienced seamstresses, it still exists, please see the chart below to see the trend of sewing speed. From above we can conclude that, if the number of order qty is larger, the sewing time spended per tool bag is shorter, more tool bags can be produced per month, and the labor cost per tool bag is lower.

Therefore, in order to improve work efficiency, reduce profit loss and obtain unit profit in unit time, the factory must calculate MOQ for orders, which is one of the reasons why the order quantity larger, the price cheaper.

Material

The tool bag factory is processing factory rather than raw material production factory, all materials used to produce tool bags need to be purchased, and there is also MOQ when purchase these materials.

Take customized fabrics as an example, assuming that the MOQ of the customized fabrics set by the fabric supplier is 1000 yards–the tool bag factory must purchase customized fabrics of no less than 1000 yards—this 1000 yards of fabric can be used to manufacture 2000 pcs Z model tool bags,If our clients only purchases 1000 pcs Z model tool bags, half of the customized fabric will be wasted, because this batch of fabrics is customized and cannot be used for other clients’ goods.

Therefore, the factory must set the MOQ of the Z model tool bags of customized fabrics to 2000 pcs.

Transportation

Let’s analyze the current global logistics status, for exporters, it is not that the more goods in the export, the higher the local transportation cost. The FCL(full container load) transportation is usually the most cost-effective.

In FCL, this fee = container arrangement fee + container shipping fee. In LCL(less than container load), this cost = freight from the factory to the warehouse of the forwarder + warehouse entry fee + warehouse storage fee + handling fee + time cost(Sometimes the trucks have to queue up to unload the goods because there are too many goods waiting to enter the warehouse, The queue time is as long as half a day or several days. The transportation company will charge this extra fee to the factory). We can easily conclude that the local cost of LCL is complex, uncertain and high risk, and these costs are different for different freight forwarders and different times. Assuming that 2000 pcs Z model tool bags fit full one 20 GP, according to a lot of past experience, the local fee for LCL of this batch of goods will be higher than FCL’s.

Therefore, in order to reduce profit loss and provide lower prices to clients, the factory have to set the MOQ to 2000 pcs.

Price/Profit

It’s complicated to describe, but in simple terms, the price is high for a small order quantity, and the price for a large order quantity is low. In fact, the unit cost of producing 1000 pcs of the same model is higher than that of 2000 pcs ‘s. In order to maintain profit margins, the factory have to quote a high price if the order quantity is 1000 pcs and quote lower price if the order quantity is 2000 pcs. If the order quantity is less than a certain number, the price will be much higher than the market price and usually cannot be accepted by the clients, and even if the clients accept it, they cannot make a profit in their market.

Therefore, the factory have to set the MOQ so that the price does not deviate from the market price and the profit margin is maintained.

Affecting Factors Of MOQ In Different Orders

Stock Orders

If the shipping method is express, MOQ is 1, as long as the clients accept the high cost of international express shipping.

If shipping by sea, the MOQ is related to the specific shipping method, pls refer to the above content “Why there is MOQ in tool bag bulk purchase?–Cost–Transportation”, Incredibly, sometimes, even at the same price, the total profit the factory makes from selling 100 pcs of the same model in stock is about the same as the total profit from selling 200 pcs.

Brand Agency Orders

If you are our brand agent, then the MOQ is only related to the agency contract.

Assuming that the contract stipulates that the buyer purchases at least 10000 pcs Z model tool bags per year and purchases at least 1000 pcs in each batch, then both parties to the contract shall trade in accordance with the contract.

OEM/ODM Orders

Both OEM and ODM orders are essentially customized bulk orders, and customization requirements are the main factor affecting the MOQ of such orders.

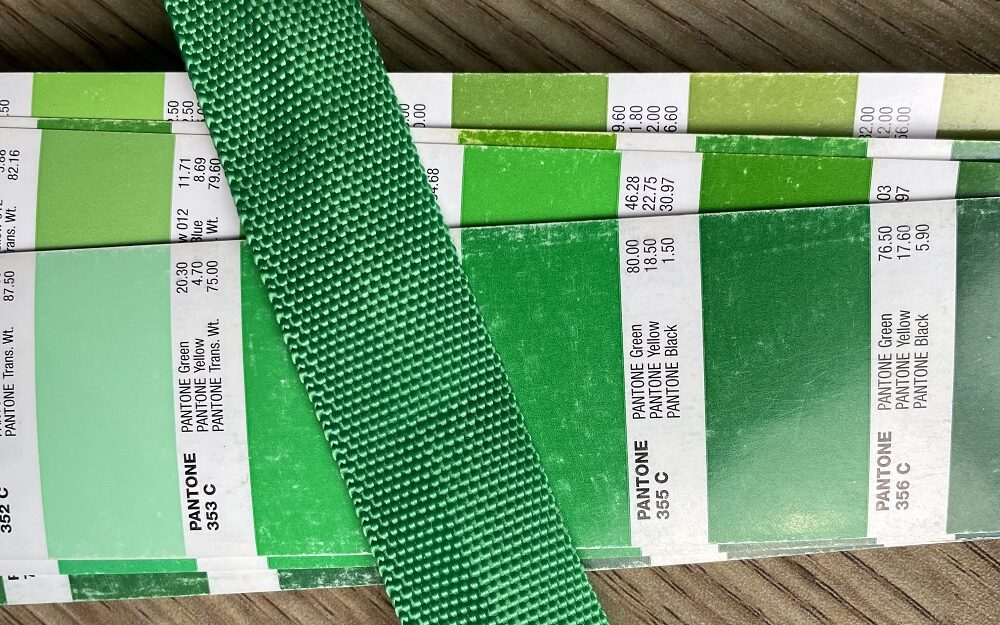

For example, the client wants to customize the fabric and webbing with a color of PANTONE 355C. Assuming that the MOQ of the customized fabric is 1000 yards and the MOQ of the customized webbing is 1000 meters, 1000 yards of customized fabric can be used to manufacture 2000 pcs customized products, 1000 meters customized webbing can be used to manufacture 5000 pcs customized products. In this case, the MOQ must be 5000 pcs. If the order quantity is less than 5000 pcs, there will be surplus in 1000 meters of customized webbing, and it is difficult for the factory to use customized materials for other orders, which is very easy to cause waste.

What If The Purchase Quantity Is Lower Than The MOQ?

I will introduce to you how we provide solutions to our clints for MOQ problems through a case, Please be noted that the data of this case is only for example and not real data, the following is the case description.

Case Introduction

Please refer to the picture below, a client wants to customize this model OT-005 tool tote, change the color of the main fabric from gray to blue PANTONE 288 C, change the color of the trim from black to dark gray PANTONE 4286 U, and change the color of the sponge grip from black & red to black & blue (PANTONE 288 C).

This case is relatively common, and not the most complicated, the solution we once provided saved one of our client 2/3 of shipping and storage costs, with no any other cost!

Find The Factors That Affect The MOQ

First we need to analyze customization requirement one by one.

1: MOQ of customized blue fabric is 1000 yards, 1000 yards of customized fabric can be used to produce 1000 pcs OT-005.

2: MOQ of customized trim is 1000 meters, 1000 meters of customized trim can be used to produce 2000 pcs OT-005.

3: MOQ of customized sponge grip is 8000. 8000 customized sponge grip can be used to produce 8000 pcs OT-005.

From above it can be concluded that, the MOQ will be as high as 8,000 pcs in order to meet all these customization requirements.

Get Solutions

If order qty is very close to 8000 pcs, we advise increasing the order qty to 8000 pcs.

If order qty 2000-8000, We advise full black sponge grip, or try to find grip in a similar color scheme in the market (but it’s very hard), there is no problem with customizing the trim and fabric.

If order qty 1000-2000, We advise to use full black sponge grip, and try to find trim with similar color in the market, there is no problem with fabric customization.

If order qty less than 1000, We advise all black sponge grip and try to find trim and fabrics in a similar color in the market.

It is worth considering:

1: Since the fabric market is very large, it is possible to find fabrics or trims with similar color. If the client accept it, this is a good way.

2: For materials like fabric or trim, our supply chain allows us to customize in quantities below the MOQ, but the cost will be higher. Yes, everything is possible, everything is negotiable!

3: If the order qty (such as 980) is very close to the MOQ (such as 1000), we will consider accepting order, which must be considered in conjunction with other situations accordingly.

Inspect Solution

Firstly, we can provide visual artwork for reference.

Secondly, after finding materials with similar color, We can provide the comparison picture of the material and Pantone color bridge or send the material sample to the client for checking.

And finally, we can make the real sample for the client to test.

All these to make client be satisfied with our solution.

How to lower the MOQ Of Tool Bag Bulk Sourcing?

Buy Stock Products

For small clients, we recommend developing your tool bag business with stock products, IRONLAND will prepare several batches of hot-selling products in stock every month, you can start with these products, and if the market feedback is good, you increase the purchase quantity.

Simple Customization

Simple customization requirements will not make the MOQ very high. If you only customize the LOGO, the MOQ may only be hundreds of products. Conversely, the more complex the customization requirements, the higher the MOQ will be.

Boost Small Business

Currently the global international trade is developing day by day. International trade is no longer just for large enterprises. Many small enterprises also start to import tool bags from China. The miniaturization of international trade orders is the trend. For this, I recorded a video to show how we boost small tool bag business.

Long-term Cooperation

If you are our long-term cooperating client, then congratulations, we can do much more for you. For example, when your customization requirements make the MOQ of single order be high, we will consider some solutions such as accepting partial shipments and partial payment. In short, everything is negotiable!