We have been manufacturing tool bags for nearly 20 years, and the quality of our tool bags has won the trust of more than one hundred clients around the world in the passed years. In order to continuously improve the quality of tool bags and protect the interests of our clients, we have summarized 6 ways.

1: Staff Training

Unqualified products are produced by unqualified employees, so employees are the first factor in quality assurance. The skill level, concept and willpower of employees are difficult to evaluate and assess, and producing tool bags is basically manual work, so the role of employees in quality assurance is even more important. Improve skills, competencies and responsibility of employee by training, all of which are considered to assure the quality of products from the aspect of “employee”.

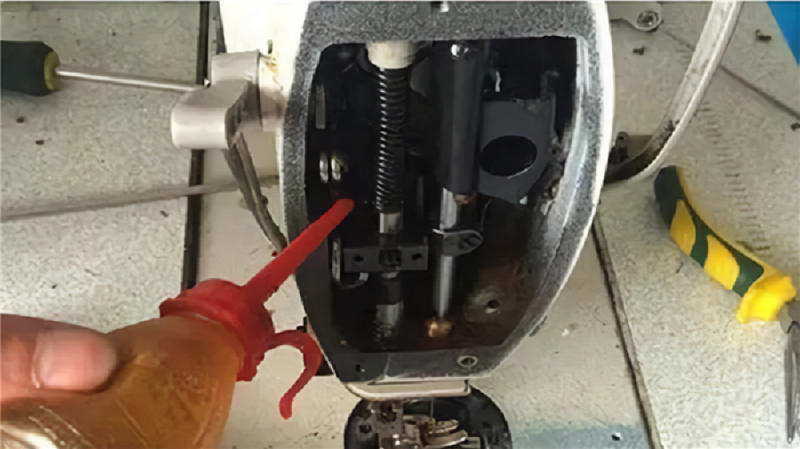

2: Maintenance Of Machines And Equipment

Machine health is the key to quality assurance, and many quality problems are caused by machine faults. For example, if the sewing machine often caused jumpers, floating threads, broken threads, tooth marks and scratches when the sewing machine is running, it is all because the sewing machine is not running healthy or is improperly adjusted. In view of this, we must do a good job in the daily maintenance of the machine, and troubleshoot in time.

3: Guarantee The Quality Of Materials

The quality of material directly affects the quality of the tool bag. Among the complaints we received from clients, many of them are related to materials, such as zippers, the common problems of zippers are discoloration and zipper jams. Therefore, we must strengthen the control of material quality, strictly control the purchasing department, material department and IQC department, strengthen communication with material suppliers, and select material suppliers with guaranteed quality. Only by guaranteeing the quality of materials can the quality of finished products be effectively guaranteed.

4: Produced By Correct And Standardized Methods

Production must follow the correct and standard method. This is what every manufacturer understands. Many quality problems are caused by non-standard production processes. Our IPQC department must carry out pre-production planning for each tool bag order, formulate a standardized and efficient plan for production, focusing on checking and guiding some difficult craftsmanship and processes, which can not only improve the efficiency of production, but also avoid quality problems.

5: Optimize Production Environment

Some people always think that the impact of the production environment on quality should not be great, which also just proves that they do not pay attention to quality assurance. In fact, qualified products can be only produced in a good working environment. If our working environment is messy, if we do not pay attention to the identification and proper storage of materials and equipment, and do not pay attention to cleanliness, then our materials, semi-finished products and finished products will easily become dirty or even deformed. In addition, working in a bad environment cannot produce efficiently.

6: Analyze The Reports Of Defective Products

We take full responsibility for all defective products caused by quality problems. Our clients are expected to make a report of defective products with quality problems and send it to us. If the report is confirmed by both parties, in addition to compensation, we will focus on the report, from which we can find the frequent quality problems and the problem in our quality assurance system, so that a targeted production plan can be formulated to continuously reduce the defective product rate of the tool bag goods and improve the quality.

Summary

To sum up, we have briefly analyzed how to carry out the quality assurance of tool bags from 6 aspects. To effectively assure the quality of products, we need everyone’s active participation and joint efforts, develop a good team spirit, control every production process. We firmly believe that only high-quality tool bags can win the trust of clients, if you are looking for a tool bag manufacturer, why not try to contact IRONLAND?